Makita 2030 Planer Manual

. 3 0 (118') size lmml Fence size 19-1 1/16') 357116') 100 1247132' lmml Overall dimensions 574 (2723132' 357116' 2219132') MODEL 2030s DOUBLE INSULATION Feed rateimin 5-29132'1 wide 9-7/16' 10.5 (34.5 wide 12-9/32' w i d e lmml (mml Stock height 160 15/32'.

For Your Own Safety Read Instruction Manual Before Operating Planer-Jointer GENERAL SAFETY PRECAUTIONS KNOW YOUR POWER TOOL. Read the owner’s manual carefully. Learn the tools applications and limitations, as well as the specific potential hazards peculiar t o KEEP GUARDS IN PLACE and in working order. EXTENSION CORDS. Make sure your extension cord is When using an extension cord, be sure t o use one heavy enough t o carry the current your product will draw. A n undersized cord will cause a drop in line voltage resulting correct size t o use depending on cord length and nameplate ampere rating. Never stick your finger into the chip chute.

View and Download Makita 2030N instruction manual online. Planer- Jointer 320 mm (12-1/2') With Electric Brake. 2030N Planer pdf manual download. Makita 2030 Planer Blades. There was a jig supplied by the company that helped position the planer blades in a Makita 2030. For Equipment Manuals 5 replies. 0S INSTRUCTION MANUAL Pdf Download. Read the owner’s manual carefully. Learn the tools applications and limitations, as well as the specific potential.

Chute may jam w h e n cutting damp wood. Turn off the planer-jointer and then clean out chips w i t h a stick. Do not touch blades right after operation, they may be extremely hot and could burn your skin. FOR AUTO-PLANER Two or more pieces of narrow but similar thickness stock can be passed through the auto-planer side by side.

However, allow some spacing between the stock t o permit the feed rollers t o grip the thinnest piece. When transporting it by vehicle, secure with a rope or other substantial means to prevent tipping or movement. Positioning the planer-jointer Locate the tool in a well lit and level place where you can maintain good footing and balance.

AUTO-PLANER FUNCTIONS: Dimensional adjustment Raise the table by turning the crank handle clockwise until the indicator plate points to the scale graduation indicating the de- sired finished dimension. One full turn of the crank handle moves the table 2 mm (3/32'). This i s especially convenient with two operators. CAUTION Workpieces with the following dimensions cannot be fed into the auto-planer because the interval between the two feed rollers i s 114 mm (4-1/2').

Do not try to cut them. Less than (4-1i2'). JOINTER FUNCTIONS: Extension support table The extension support table i s convenient for cutting long workpieces.

Install it on the outfeed table and semi-tighten the four hex bolts. Extend the legs arms over the screw using the hook Then tighten the screws securely. Adjust the table height using the knobs so that the extension support table i s level with the outfeed table. Adjusting the fence angle The fence angle can be adjusted angle from 0’ to 45’.

Loosen the clamp screws ( A ) and (B) and pull the fence out slightly. Then tighten the clamp screws (A) and (B). Loosen the hex bolts ( A ) and (B) and tilt the fence according to your work. Carefully maintain flush, steady con- tact with the fence while making the cut.

REPLACING THE PLANER BLADES Dull blades can cause a rough finish, an overload of the motor and dangerous kickback of the workpiece. Sharpen or replace dull blades immediately. This tool is equipped with either throw-away blades or standard blades. The magnetic holder has a different shaped claw on each side. Use the cor- rect claw for auto-planer. Place the two magnetic holders on the set plate and push them in the direction of the arrow until the claw contacts the blade. Remove the eight blade installation bolts using the socket wrench.

Place the two magnetic holders on the push them until the claw contacts the blade (Note: Use the correct claw for auto-planer. Grip the magnetic holders and slip the heel of the plate into the groove in the drum. Install the blade installation bolts. Install the other blade as described above. Rotate the drum slowly while pressing the lock plate to make sure there i s nothing abnormal. Then close the chip cover and secure using the hex bolt. CAUTION: Do not tighten the blade installation bolts without the blade locating lug of the correctly resting in the groove of the blade.

Removing the blades CAUTION Always close the chip cover over the auto-planer before removing the blade. Lower the infeed table fully by turning the depth adjusting knob clockwise. Loosen the hex bolt which secures the safety cover rod and lift off the safety cover. Installing the blades Provide a flat wood block approx. 150 mm (5-29/32') long and 100 mm (3-1 5/16') wide. Place the blade and plate on the wood block so that the blade locating lug of the set plate rests in the groove of the blade.

Adjust the plate so that both ends of the blade do not protrude from the ends of the plate. Lock the drum in the position whereby the blade edge faces upward. Place the triangular rule flat on the outfeed table.

Makita N1900b Planer Manual

Turn the adjusting screws until the blade edge just contacts the triangular rule. After adjusting both adjusting screws, pull the lock pin to unlock the drum. Install the other blade position and be sure that the safety cover works properly and briskly. CAUTION: Do not tighten the blade installation bolts without the blade locating lug of the set plate correctly resting in the groove of the blade. This may cause damage to the blade and potential injury to the operator.

Always be sure that the tool is switched off and unplugged before removing or installing the jointer. The jointer can be easily removed from the auto-planer.

You can carry it by yourself. Removing the jointer Loosen the right and left knobs. Align the two shafts of the jointer with the mating holes in the auto-planer.

Push the jointer toward the auto-planer until the frame of the jointer contacts that of the auto- planer. To maintain product SAFETY and RELIABILITY, repairs, any other maintenance and adjustment should be performed by Makita Authorized or Factory Service Centers, always using Makita replacement parts only. Brush holder cap Limit mark Screwdriver. ACCESSOR ATTENTION: These accessories or attachments are recommended for use with your Makita tool specified in this manual. The use of any other accessories or attachments might present a risk of injury to persons. The accessories or attachments should be used only in the proper and intended manner. M a r - 2 2 - ’ 9 4 (12-9/32”) PLANER-JOINTER Model 2030s.

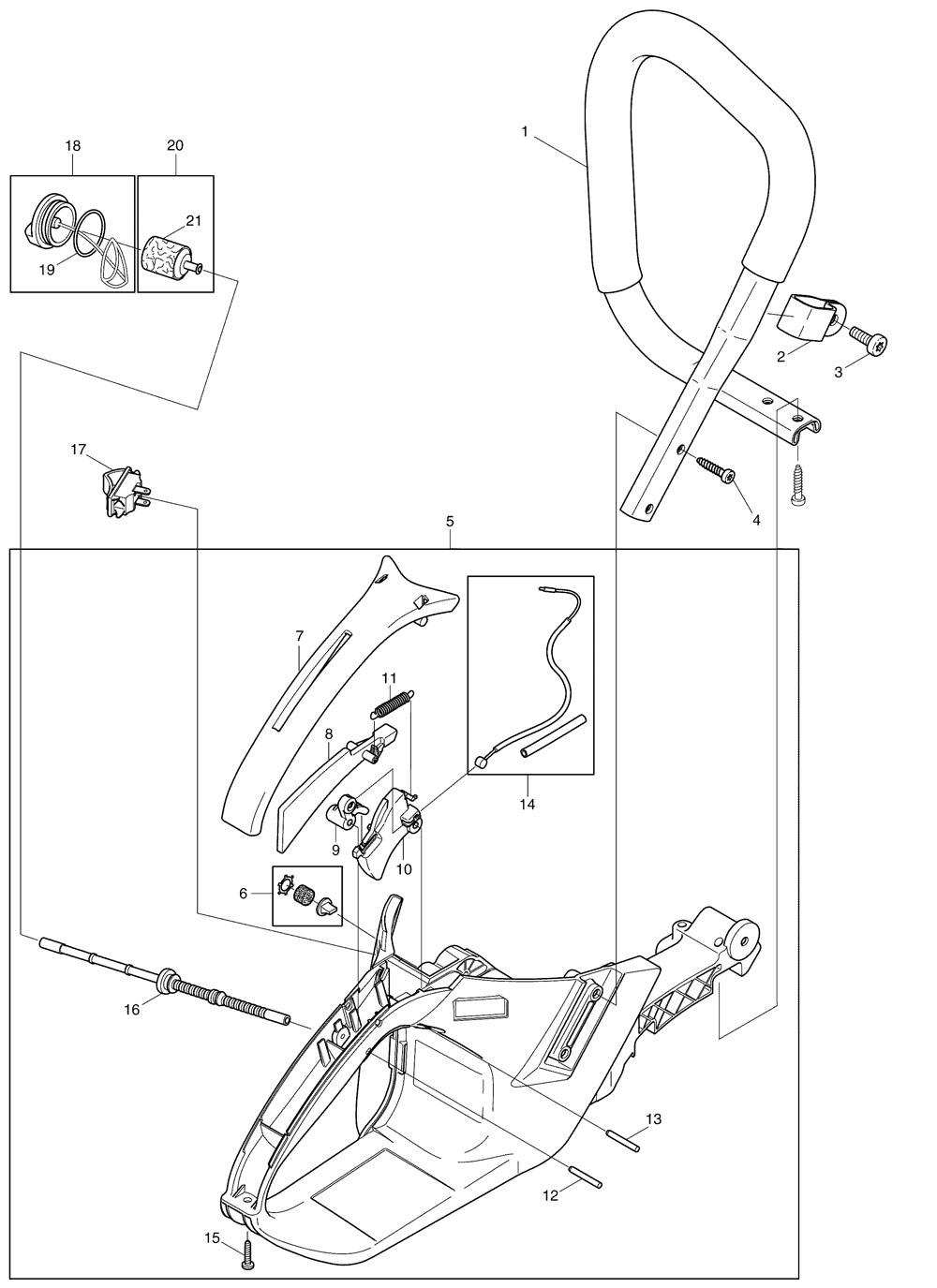

Note: The switch and other part configurations may differ from country to country. Strain Relief Tapping Screw Flange PT4x12 Tapping Screw Flange PT4x12 Strain Relief Switch Box Cover Name Plate G W nouslng Makita Label Flat Washer 12 Helical Gear Woodruff Key 4 Drive Shaft Flat Washer 1 4 tiouslng C O W. 20305 MODEL ' y 0 M DESCRIPTION MACHINE Hex Flange Head Bolt M6x17 Foot Base Cover Pan Head Screw M5x16 IWith Washer) Spring Pin Base Cap 2 0 Drum cover Retaining Ring S p r i n g P i n 4 - 1 6 Spring Pin 4 - 3 2 Rod 1 2 - 9 5 Spring 14. MAKITA LIMITED O N E YEAR WARRANTY Warranty Poiicy Every Makita tool is thoroughly inspected and tested before leaving the factory. It is warranted to be free of defects from workmanship and materials for the period of ONE YEAR from the date of original purchase.

Bob, Thanks for the reply. Yes, the fig 27 and page 23 knob is for adjusting the infeed bed for depth of cut. No problem there. My question was poorly worded. The problem is one of alignment of the infeed and outfeed beds. The infeed bed has a 1/32' sag at the entry end.

That is, if I bring the beds to zero cut and place a straight edge on the beds, a gap is visible at the end of the entry bed farthest from the cutters. As a result, the wood being jointed develops a convex curve.

I'm looking for a way to adust the alignment so both beds are exactly parallel with each other. Regards, Gary BobS 08.04.08 10:17. BobThanks for the reply. Yes, the fig 27 and page 23 knob is for adjusting the infeed bed for depth of cut. No problem there.

My question was poorly worded. The problem is one of alignment of the infeed and outfeed beds.

The infeed bed has a 1/32' sag at the entry end. That is, if I bring the beds to zero cut and place a straight edge on the beds, a gap is visible at the end of the entry bed farthest from the cutters. As a result, the wood being jointed develops a convex curve. I'm looking for a way to adust the alignment so both beds are exactly parallel with each other. Regards, Gary Gary, The site and the manual do not show the alignment procedures that I can see, so.

Tear into it and remove the infeed table. See if you can find any adjustments and if not, then you have to use the practice that is typically used on jointers - adding shims on the slides that the infeed table rests on. Other than that - call the company and ask. G Mulcaster 08.04.08 20:32.

On a 29 inch long infeed table that might not be a lot. Is there any chance there is a technique issue or maybe blades too proud? Looking at my Makita I see no adjustment. Unless the jointer really got wacked I would suspect it was dead on from the factory. I do not have a certified straight edge but my 6' level show no problems on my Makita 2030. Are you ignoring the pointer on the jointer and testing this with a known good straight edge at least 5 feet long? That pointer adjusts.

Are you sayin when you place a 6 foot straghtedge on both beds and crank the infeed up to even with the outfeed by the cutter that 29' from the cutter you observe a 1/32' gap? If the infeed table is caddywompus there are 4 bolt underneath that may allow for minor shifting to adjust a twisted infeed table. You need an anti-caddywompus guage though. How about a picture? G Mulcaster 09.04.08 19:30.

I have a Makita 2030 Planer-Jointer and the jointer infeed table needs adjusting. Does anyone know how to adjust these? No luck at the Makita manuals download site. Thanks for any help. On a 29 inch long infeed table that might not be a lot. Is there any chance there is a technique issue or maybe blades too proud? Just checked.

Blades are level with the outfeed table. That is, if I place the two pieces of teak on the rear bed, the cutters barely touch the teak. Ditto if I raise the infeed table level with the outfeed table. When the pieces lay across both beds, the cutters barely touch them. Looking at my Makita I see no adjustment.

Unless the jointer really got wacked I would suspect it was dead on from the factory. I do not have a certified straight edge but my 6' level show no problems on my Makita 2030. The 2030 is quite old, and has been dead on until this year. (An exception noted below). Are you ignoring the pointer on the jointer and testing this with a known good straight edge at least 5 feet long? That pointer adjusts. Are you sayin when you place a 6 foot straghtedge on both beds and crank the infeed up to even with the outfeed by the cutter that 29' from the cutter you observe a 1/32' gap?

I use a 6' straight edge. When I lay it on the tables, the straightedge is flush with the whole length of the outfeed table. It contacts the cutter end of the infeed table and a 1/32' gap shows at the other end of the infeed table. If the infeed table is caddywompus there are 4 bolt underneath that may allow for minor shifting to adjust a twisted infeed table. You need an anti-caddywompus guage though.

Aug 19, 2010 Newest MF Doom - or DOOM now- album 'Born Like This'. Great story, great flow, great collabs. Posted by Danny at..rar Files; Sir. Mf doom born like this youtube.

Can't find the bolts - nor do I see them in the manual (2030N). How about a picture?

I don't think the gap will show. I'm thinking it might be a temperature problem. I now recall having the same issue last Winter when I once tried to use it in my unheated garage. During the following Summer there was no problem. This year my garage is heated and I'm now in there often.

Since I only have the heat on during the day, the machine (which is a big chunk of metal subject to heating/cooling effects) may not warm up enough. We have some warm weather on the way to check my theory. Thanks for taking the time to respond. Gary Jim Behning 09.04.08 20:28. I seem to have one large spring loaded bolt holding the infeed table on the sloped rails.

The rails are fluted (?) to ensure the infeed table stays in lateral alignment. The 2030 now in my basement I have used on occasion since about 1990. It has always been in a stable environment generally ranging from 72-78 degrees with little temperature fluctuation.

Well you have a stumper and maybe temperature is having an effect. Will know soon. Warm weather enroute:) Regards, Gary G Mulcaster 04.05.09 18:20. On Mon, 7 Apr 2008 20:20:01 -0400, 'BobS' wrote: 'G Mulcaster' wrote in message news:eihgv3hnal86b4kksg1m8ki27khdntedbo@4ax.com. Hi folksI have a Makita 2030 Planer-Jointer and the jointer infeed table needs adjusting. Does anyone know how to adjust these?

No luck at the Makita manuals download site. Thanks for any help. Regards, Gary Just a follow up. I never did get the infeed table adjusted; it still sags about 1/32' at the infeed end. However, at long last I had the blades sharpened. Now, finally, the jointer works perfectly with no convexing (new woodworking term) of the boards. I love my Makita 2030 again:) Gary bernar.@gmail.com 10.10.14 12:22.